What Is a Blister Pack Machine? Everything You Need To Know

10 Tips For Buying Your First Blister Packaging Machine

The Ultimate Guide to Semi Automatic Capsule Filling Machine: Everything You Need to Know

1. Overview

There is a high demand for semi automatic capsule filling machines from pharmaceutical manufacturers around the world. Some hospitals and drug R&D institutions also use them. The main purpose of a capsule filling machine is to feed capsules. However, they can also ensure proper alignment and vacuum sealing of the capsules. This reduces issues like capsules not falling into place correctly.

semi automatic capsule filling machines have quick change parts that can be swapped out in 5-8 minutes. Older models took 30+ minutes, but the newer versions come with user-friendly features. They have advanced controls with touchscreens and sensors as well. It helps the users to automate capsule counting and filling process. This replaces manual filling work and reduces labor. Hence, getting a semi-automatic capsule filling machine is one of the best investments you can do.

Installation and Maintenance of semi automatic capsule filling machines

Here’s an overview of the process to follow when installing and maintaining semi automatic capsule filling machines. It is important to stick to manufacturer recommendations at all times to ensure longevity of the machine.

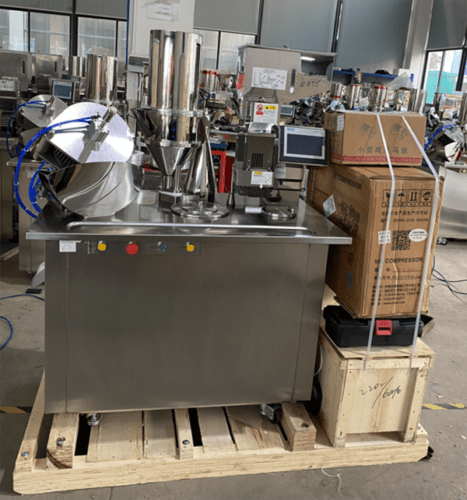

1. Unpacking and Inspection

Upon receiving the machine, inspect all components and accessories. This will help you to make sure that nothing is missing or damaged compared to the packing list. Check for any damage that may have occurred during shipping. The machine should be installed indoors in a space with adequate ventilation and low humidity.

2. Cleaning and Grounding

Before powering on the machine, thoroughly clean all surfaces using a soft cloth lightly dampened with soap and water or a mild detergent. Wipe dry with a separate soft cloth. Connect the machine to a properly grounded 380V/50Hz 3-phase power supply. Ensure the grounding wire is attached to the grounding port marked on the machine.

3. Authorized Personnel to Operate and Maintain

You shouldn’t allow anyone to use this machine. Instead, make sure that only people who know how to use it correctly access the machine.

They include:

- Staff members who received a proper training on how to use the machine.

- Individuals who have a thorough understanding of the user manual.

- People who are familiar with the structure of the machine and know how to operate it

Individuals who are qualified to work on machine maintenance.

4. Routine Maintenance

Routine maintenance can help you enhance the longevity of the capsule filling machine. This is where you should pay attention to the moving parts, such as gears, shafts, and cams. Moreover, you need to pay special attention to the transmission system and oil it. Utilizing laser cleaning for certain components can ensure a more thorough and non-abrasive cleaning process. Always refer to the user manual when conducting inspections.

3. Major Technical Parameters

| Mould Changing Time | 5-8(mins) |

| Working Capacity | 25000-30000(pcs/hour) |

| Suitable Capsule Size | 000#、00L#、00#、0L#、0#、1#、2#、3#、4# |

| Power Supply | 380V 50Hz 3PH 4.0kw |

| Compressed Air | 0.03m/min 0.7Mpa |

| Vacuum Pump | 40m³/h |

| Overall Dimension(LxWxH) | 1.14x0.7x1.63m |

| Machine Weight | 380kg |

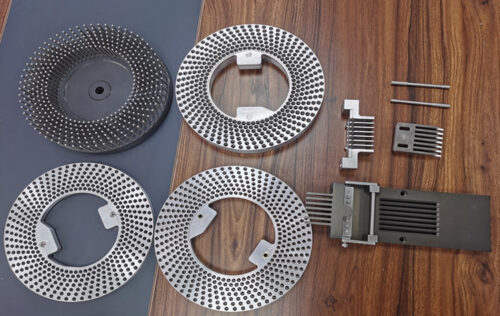

4. Key Components of a Capsule Filling Machine

A capsule filling machine is made out of few key components. Let’s explore what those components are and how they make up the entire system.

- Feeding station

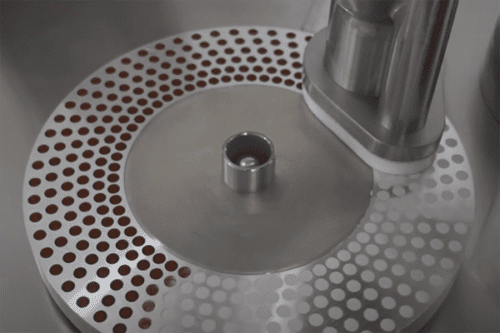

The feeding station uses a sector gear mechanism to drop capsules from the hopper into the feeding tube. A reed switch is triggered by an iron piece each time the tube drops. It releases a row of capsules. The station uses a cam, rocker arm, and ratchet drive powered by a separate motor. An automatic counter stops the machine when the disk is fully loaded.

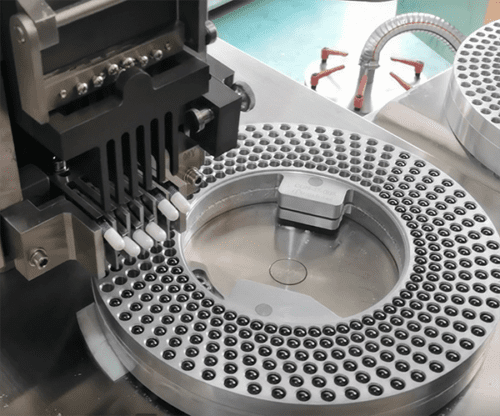

- Filling station

The filling station automatically fills the capsules in the disk with powder from the hopper. The hopper has a stepless speed control motor driving a propeller to force powder into the empty capsules. A turntable rotates the disk under photoelectric control. Pressing the "Start Filling" button pushes the hopper against the disc with a cylinder to complete the filling process.

- Joining station

The joining station connects the filled capsule bodies and caps using the upper and lower disks. Stepping on a foot pedal valve activates a capsule-ejecting cylinder with pins. It will push out the filled capsules into a collection bin.

- Air Control System

The 0.4-0.7 MPa air system uses an air pump and FRL unit to supply compressed air. The air is directed by a foot valve and solenoid valve to control the speed of the cylinders.

- Electronic Control

The 380V 50Hz 3-phase 4-wire electrical system (custom voltages available) has a separate grounding wire. Three separate drive motors independently operate different transmission components for convenient operation and maintenance.

5. How To Work

Cleaning and Preparation

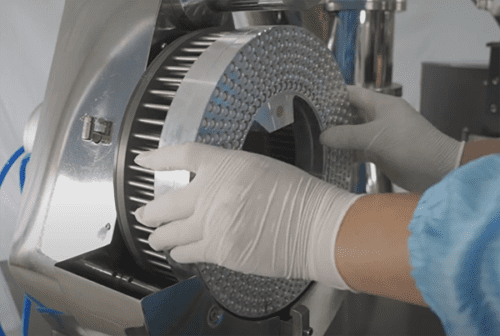

- Inspect all equipment and components to ensure proper working conditions. Clean and sanitize according to standard cleaning procedures.

- Install the required capsule feeding assembly, pin disk, and capsule disk for the production run.

Startup

- Turn on the air compressor and adjust pressure to 0.5-0.7 MPa.

- Start the vacuum pump motor, install the capsule disk, and press the capsule feed button to initiate automatic capsule feeding. After one feed cycle, rotate the disk to separate capsule bodies and caps.

Filling Capsules

- Remove the upper disk and place the lower disk with bodies into the filling station.

- Press the fill button to automatically rotate the powder hopper into position over the disk and begin powder filling. Filling stops after one full rotation.

If fill levels are unsatisfactory, adjust the fill speed.

Joining and Collection

- Rejoin the upper and lower disks and place them into the locking station. Close the blocking plate and step on the pedal to open the air valve to lock the capsules.

- Move the disks towards the ejector pins which will push the filled capsules into the collection chute.

- Emergency Handling

- If an emergency occurs, immediately press the red stop button.

6. Safety Precautions to Take When Operating the Capsule Filling Machine

- Strictly follow all operating procedures. Never take unnecessary risks or endanger yourself or others.

- Thoroughly read and understand the operating manual, especially all safety precautions, before using the machine.

- Do not open protective covers or adjust the machine while it is running to prevent accidents.

- Routinely check components for damage or looseness. Promptly replace or tighten any damaged parts to maintain proper working condition.

- Disconnect power and ensure the machine has fully stopped prior to any cleaning. Use only appropriate tools to avoid damaging surfaces.

- Never place hands or objects into a running machine to avoid injury.

- Position the machine in a stable, dry, well-ventilated area, avoiding direct sunlight or damp conditions. Allow sufficient access for maintenance.

- Immediately stop the machine if any abnormal sounds, vibrations, or overheating occur. Do not restart until the issue is resolved.

- Operators should wear work gloves and protective work clothes for safety.

- Provide regular safety training to staff to ensure awareness of hazards and improve skills.

7. Steps to Follow During Routine Maintenance

- Clean all exterior and interior surfaces regularly to prevent dust buildup.

- Routinely check and tighten any loose component fittings or fasteners.

- Check lubricant levels in all transmission points and add oil as needed.

- Inspect wiring and cables for damage and loose connections. Replace aging wires and cords promptly.

- Perform regular comprehensive inspections, including both mechanical and electrical systems, to identify worn or damaged parts.

- If any fault or damage is found, immediately stop the machine and contact qualified repair personnel to service and replace parts as needed. Adhere to all lockout/tagout procedures.

8. Adherence to Procedures

- Operators must follow all operating procedures to ensure proper machine function and personal safety.

- Only trained and authorized personnel may operate the equipment.

- Consult technical contacts or supervisors promptly if any procedure is unclear.

- Management reserves the right to interpret or modify procedures as needed. Changes must be communicated to staff. Retrain when necessary.

- Strict adherence to these operating procedures will ensure safe and proper machine function. This can eventually help you improve production efficiency and reduce failures. In the long run, it can support company production goals and development.

Conclusion

Now you have a clear understanding of how to use a semi-automatic capsule filling machine. Make sure to follow the instructions we shared when using a one. If anything is not clear or if you need additional information, feel free to get in touch with us. One of our specialists will get in touch with you within 24 hours of receiving your email.

Related Articles:

What is a Semi-Automatic Capsule Filling Machine and How it Works?

What Is a Capsule Filling Machine? Everything You Need To Know

Top 10 Capsule Filling Machine Manufacturers In The World(2024)