Vacuum Emulsifying Tank Applications in Pharmaceutical Manufacturing

How to Make Gummy Candies at Scale: Production Lines & Equipment

Vegetable Capsules: Benefits, and Capsule Filling Machine Compatibility

Introduction

As capsule manufacturers navigate an evolving market, vegetable capsules have emerged as a game-changer in supplement and pharmaceutical production. These plant-based capsules offer an alternative to traditional gelatin, aligning with rising consumer demand for clean-label, vegan-friendly products.

In fact, increasing preference for plant-based and vegetarian capsules is prompting capsule makers to innovate with new materials that match gelatin’s functionality while appealing to a broader customer base[1]. In this blog post, we’ll explore what vegetable capsules are, their key benefits for manufacturers, how they integrate with capsule filling equipment, and why brands like Grand are leading the way in efficient capsule production.

Understanding Vegetable Capsules and Their Plant-Based Composition

Vegetable capsules are typically made from plant-derived materials like cellulose (HPMC) or pullulan, providing a vegetarian alternative to gelatin capsules. Vegetable capsules (also called vegetarian capsules) are made from plant-based materials such as modified starches, pullulan (fermented tapioca), or most commonly cellulose derivatives like hydroxypropyl methylcellulose (HPMC).

Unlike gelatin capsules that are produced from animal collagen (e.g. bovine or porcine sources), vegetable capsules contain no animal products, making them suitable for consumers with dietary restrictions, including vegans, vegetarians, and those requiring halal or kosher compliance. These capsules consist of the same two-piece structure (a cap and a body) as gelatin capsules, delivering a similar user experience in terms of swallowing and dissolving. Importantly, plant-based capsule shells are free of common allergens and preservatives, and have no known health hazards – an attractive feature for health-conscious brands and consumers. In short, vegetable capsules provide a plant-based encapsulation solution that offers comparable function to gelatin capsules while satisfying ethical and dietary preferences of a growing segment of the market.

Plant-Based Vegetable Capsules for Supplements: Key Benefits for Manufacturers

Vegetable capsules offer several key benefits that capsule manufacturers can leverage, especially in the nutraceutical and supplement space. First, they dramatically expand the potential consumer base. Because they are made from plant sources, plant-based vegetable capsules for supplements accommodate customers who avoid animal products for lifestyle, religious, or allergy reasons. By using vegetable capsules, manufacturers can label products as vegan or vegetarian, tapping into the booming demand for plant-based supplements. These capsules are also generally considered hypoallergenic – unlike gelatin (an animal protein that can trigger allergies), HPMC and other cellulose polymers are far less likely to cause adverse reactions. This makes vegetable capsules a safer choice for sensitive individuals and adds a “clean-label” appeal to products.

From a production and quality standpoint, vegetable capsules bring some technical advantages. They have a naturally low moisture content (approximately 3–7% water) and exhibit strong resistance to humidity. This means vegetable capsules are ideal for moisture-sensitive ingredients and even for liquid or gel fills that might destabilize gelatin capsules. In fact, HPMC capsules maintain their structural integrity in both dry and humid conditions, whereas gelatin shells (with 13–17% water) can become brittle in dry air or may soften and deform in high humidity. Manufacturers filling water-based liquids, oils, or hygroscopic powders often prefer vegetable capsules because they remain stable without special precautions – gelatin capsules, by contrast, may require banding or sealing to prevent leakage or disintegration when filled with liquids. Additionally, vegetable capsules tend to dissolve readily and reliably.

Vegetable Capsules Compatible with(Capsule Filling Machines)

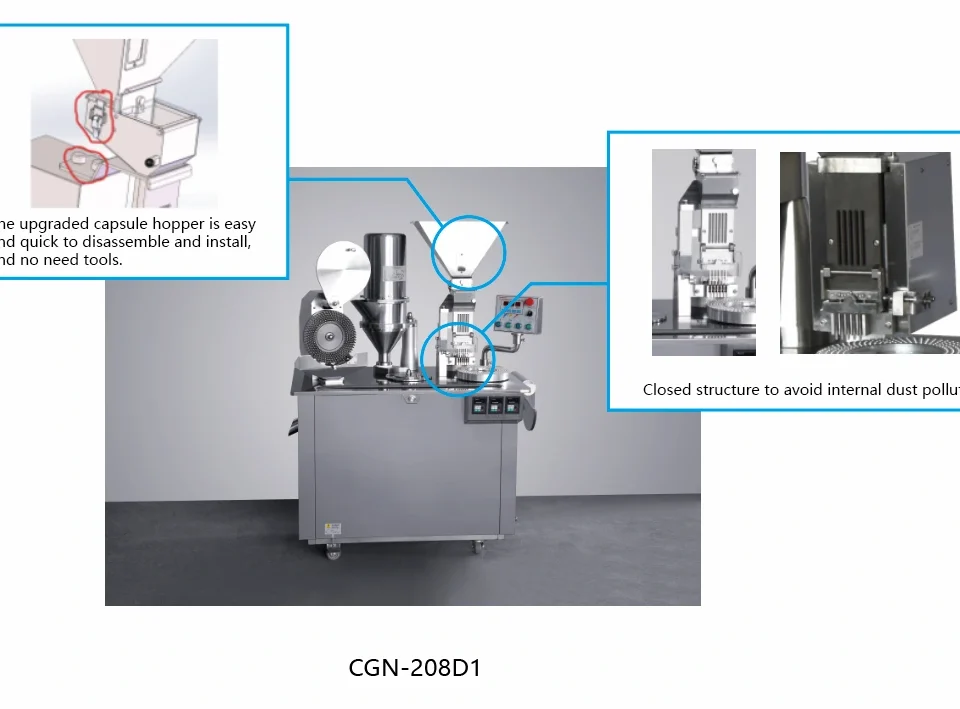

Modern capsule filling machines like the Grand NJP-series are designed to handle both gelatin and vegetable capsules with high precision and speed. One concern capsule manufacturers might have is whether vegetable capsules are compatible with standard capsule filling machines.

The good news is that vegetarian hard capsules are fully compatible with virtually all modern filling equipment. Their dimensions (sizes 000# through 5# and others) follow the same industry standards as gelatin capsules, allowing them to be used interchangeably in automatic and semi-automatic encapsulation machines. The filling process – separating the cap from the body, depositing the fill material, and rejoining the halves – works the same for vegetable capsules. High-quality capsule fillers are typically calibrated to handle both gelatin and HPMC capsules without issue. For example, Grand’s capsule filling machines are explicitly designed to work seamlessly with all types of hard capsules, including gelatin, halal, and vegetarian capsules. Manufacturers do not need separate equipment or major adjustments to switch from gelatin to vegetable capsules in production.

Harnessing Grand Capsule Filling Machines for Plant-Based Capsules

While vegetable capsules themselves bring many benefits, pairing them with the right filling technology maximizes manufacturing efficiency. The Grand brand of capsule filling machines has become synonymous with reliability and innovation in this field. Grand’s equipment offers versatility and precision that cater to both gelatin and vegetable capsules in high-speed production. For instance, the Grand NJP-series automatic capsule fillers can handle capsule sizes from 000# to 5# and even elongated capsules, with filling speeds around 1,200 capsules per minute on models like the NJP-1200. These machines accurately fill a variety of formulations – from fine powders and granules to pellets or even liquids – all with minimal downtime and spillage. The NJP-1200, for example, is lauded for its “compact structure, low noise, accurate filling and smooth operation”, which means manufacturers can maintain consistent quality and output when scaling up production of vegetable-capsule supplements.

Grand’s capsule fillers are engineered to accommodate the unique characteristics of vegetable capsules. Features like adjustable tamping mechanisms and gentle vacuum systems ensure that the slightly more rigid HPMC capsules are separated and sealed without cracks or losses. The precision dosing technology in Grand machines ensures each capsule – whether gelatin or vegetable – is filled to the correct weight, which is crucial for product efficacy and regulatory compliance. The result is a win-win: consumers get high-quality plant-based capsule products, and manufacturers enjoy a streamlined, reliable manufacturing process backed by Grand’s expertise.

Industry Trends: Rising Demand and Market Growth for Vegetable Capsules

The shift toward vegetable capsules is not just a niche preference—it reflects a broader industry trend with significant growth potential. Market research indicates that the vegetarian (non-gelatin) capsule segment is expanding faster than traditional gelatin capsules, in line with consumer wellness trends. For example, the global empty capsules market report notes that demand for plant-based, clean-label capsule options is one of the key drivers of industry growth. Many nutraceutical brands now advertise their use of plant-based vegetable capsules for supplements, which has become a selling point as consumers seek products aligning with their values. This trend is borne out in market projections: one analysis projects the vegetable capsule market to grow at roughly 8.7% CAGR from 2025 to 2033, signaling significant expansion opportunities for manufacturers. The growth is fueled by several factors – chief among them being the rising consumer preference for vegetarian and vegan products, increased awareness of health and sustainability, and wider adoption of veggie capsules in the pharmaceutical sector for their functional advantages.

By embracing vegetable capsules, manufacturers can stay ahead of the curve and cater to a diversifying global market. Capsules made from HPMC or pullulan not only appeal to the growing vegan/vegetarian consumer base, but also address concerns about clean-label ingredients and gelatin alternatives in markets like North America and Europe (where supplement buyers often scrutinize excipient sources). In regions of Asia and the Middle East, offering halal- or vegetarian-certified capsules can open doors to new customer segments.

All these factors underscore that vegetable capsules are not a passing fad but rather a robust and growing segment of the capsule industry. For capsule manufacturers, aligning with this trend by investing in vegetable capsule production and compatible machinery (like Grand’s filling equipment) will be key to staying competitive in the coming years.

Conclusion: Embracing the Future with Vegetable Capsules and Advanced Filling Technology

In conclusion, vegetable capsules represent a compelling advancement for capsule manufacturers aiming to meet modern consumer demands without compromising on performance. These plant-based capsules provide a host of benefits – from broader market appeal and allergy safety to superior stability for certain formulations – that can elevate a supplement or pharmaceutical product line.

By leveraging high-quality equipment like Grand’s capsule filling machines, manufacturers can ensure that the shift to vegetable capsules is smooth, efficient, and profitable. The Grand brand’s commitment to precision and versatility in filling technology means that whether you’re producing a vegan herbal supplement or an innovative plant-based nutraceutical, your operations remain optimized and reliable.

The era of plant-based capsules is here to stay, driven by health-conscious consumers and global trends toward sustainability. Capsule manufacturers who embrace vegetable capsules position themselves as industry leaders – delivering products that align with ethical values and next-generation quality standards. By pairing these capsules with the right filling machinery and expertise, such as the solutions provided by Grand, companies can successfully modernize their production.

In doing so, they not only cater to current market trends but also future-proof their business in a landscape where innovation and adaptability are key. The benefits of vegetable capsules, combined with advanced capsule-filling technology, empower manufacturers to produce superior supplements and medications that truly encapsulate the best of both science and nature.

References

[1]Empty Capsules Strategic Business Report 2025: Market to Reach $4.4 Billion by 2030.May 08, 2025