Development History of Blister Packaging Machine

The Blister Packaging Process: A Complete Step by Step Guide

Tablet Counting Machine: Introduction, Working Principle, Types, Main Components and Tips to Buy

Are you in the pharmaceutical manufacturing industry? Then you will come across the need to get a tablet counting machine. However, these machines are also popular in pharmacies, hospitals, and other medical facilities. Read on this guide and learn more about tablet counting machines before making a purchase.

What Is A Tablet Counting Machine?

As the name suggests, the role of a tablet counting machine is to count tablets. It can provide assistance with counting tablets or capsules fast. Behind a tablet counting machine, you can find some advanced technologies. That’s why these machines are capable of counting tablets that come in different shapes, sizes, and colors. Moreover, they are able to sort and count different medications at the same time.

Types Of Tablets Counting Machines

When looking at tablet counting machines, you will figure out that they come in different types. Here’s an overview of them.

Manual Tablet Counting Machines

Manual tablet counter photo

These are the most basic type of tablet counting machines available. They come with counting trays made out of stainless steel or plastic. There are evenly spaced holes in a machine to sort the tablets. Then you will be able to count them manually. This requires some manual effort, consuming a considerable amount of time.

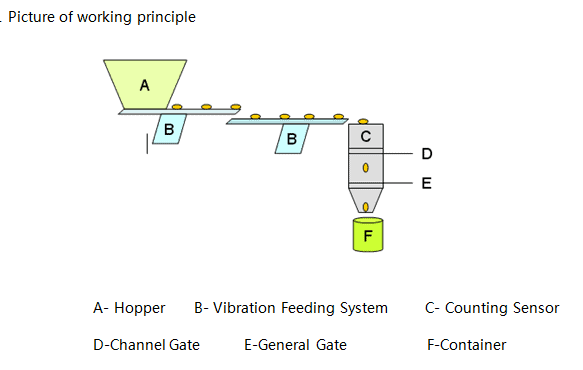

Semi-Automatic Tablet Counting Machines

SEMI Automatic Tablet Counting Machine Photo

The semi-automatic tablet counting machines offer automation up to a certain level. These machines usually come in tabletop designs. There is a feeder, which you can use to load the tablets. Then you can get them to place inside bottles. Inside these machines, there are photoelectric sensors. These sensors are responsible for counting. As a result, the counting speed is faster than the manual process.

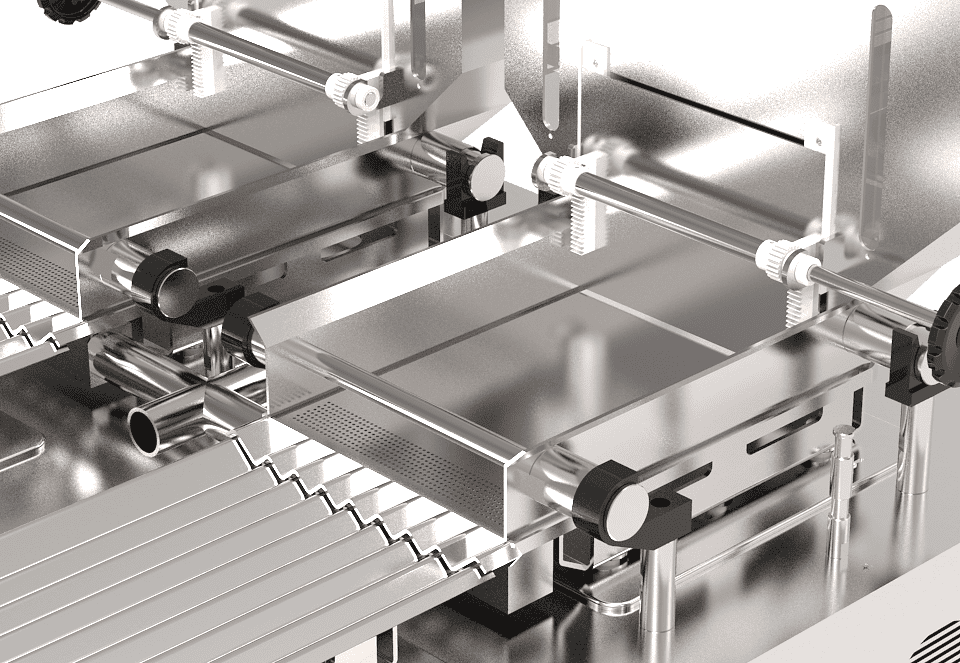

Automatic Tablet Counting Machines

Automatic Tablet Counting Machines

Fully automatic tablet counting machines are relatively advanced devices. They come with conveyors, photoelectric sensors, and many other automated mechanisms. As a result, you can ensure efficient counting of tablets, while keeping errors low. You can get a touchscreen interface in these machines. Hence, you can easily monitor the overall tablet counting process as well. If you are into producing pharmaceuticals at high volumes, you should get an automatic tablet counting machine.

What are the Parts of a Tablet Counting Machine?

Tablet Counting Machines have three main components:

The Hopper

The hopper is the large compartment at the top where you pour in the pills and tablets you want to count. It has a funnel shape, so the tablets slide down into the counting mechanism smoothly. The hopper often has a cover to prevent spillage and contains baffles to prevent jams.

Adjustable Feed Gate

The adjustable feed gate controls the flow of tablets into the counting mechanism. By raising or lowering the gate, operators can fine-tune the rate at which tablets enter to ensure smooth, precise counting.

Vibratory Plates

Vibratory plates gently shake the tablets to organize them into a neat single file line before counting. The plates oscillate rapidly to manipulate the tablets using controlled vibration for reliable alignment and counting.

Filling Funnel

The filling funnel sits atop the counting machine and serves to guide tablets into the system. Its shape and angled design provide a route for tablets to smoothly descend into the feed gate for transit to the counting plates below.

The Counting System

There are different types of counting systems, but most work by using mechanical gates, flaps, or switches that drop one pill at a time through the system. Optical and electronic sensors precisely count each tablet as it passes key points along the internal pathways. Advanced systems detect the size and shape of tablets to improve accuracy.

Bottle Conveyor

Many large tableting counting machines feature a bottle conveyor system. This automated conveyor belt seamlessly moves empty bottles into the filling station for counted tablets to discharge. The speed and motion are electronically regulated for a steady, controlled pace.

The Catch Tray

Finally, the counted tablets slide down and collect in the output catch tray. This tray is divided into compartments that organize the counted pills for easy handling. Many tablet counters have trays that hold 100+ tablets per section. The catch tray is removable so you can easily handle the counted medicines.

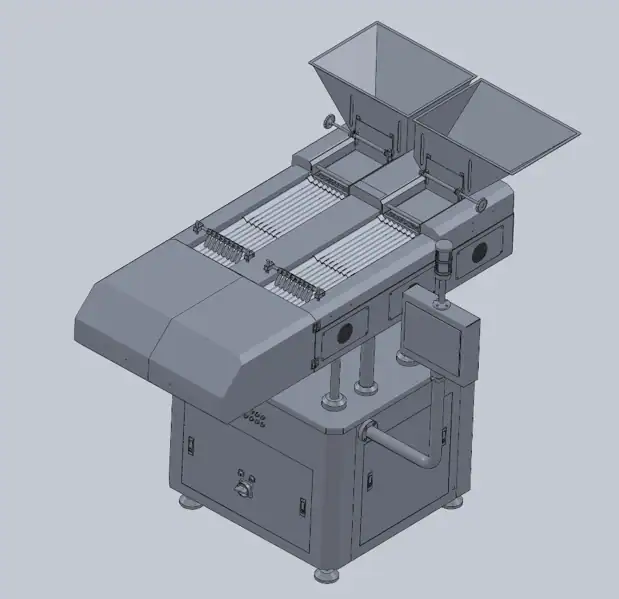

What Is The Working Principle Of A Tablet Counting Machine?

The working principle would vary depending on the type of tablet counting machine you get. To be clear, let’s deep dive and explore different types of machines and how to use them in detail.

Tablet Counte working principle picture

How does a manual tablet counting machine work?

As you already know, a manual tablet counting machine is a hand operated device. It has a hands-on, simple counting process. Here are the steps to follow:

Step 1: You should first manually pour all the pills to count into the flat tray.

pills to count into the flat tray

Step 2: Next, you need to shake the tray. This can help you with removing excessive pills.

shake the tray

Step 3: Continue to shake. As you do it, all the holes will fill up with pills. You need to do this until you fill all holes.

filling all tablets holes

Step 4: Next, squeeze the handle on the counting machine. Then you can release all the pills to the chute.

squeeze the handle

Step 5: You can now tilt the tray and let the pills fall inside your bottle.

fill all tablets in the bottle

How does a semi-automatic tablet counting machine work?

A semi-automatic tablet counting machine has a manual and an automatic process. Here are the steps you should follow:

Step1: You need to pour all the tablets inside the feeding hopper of the machine. The feeding hopper usually comes with a vibrating mechanism. As a result, you can spread the pills out and ensure that clustering will not happen.

pour tablets inside the feeding hopper

Step2: The hopper will feed all the tablets into a turntable. The turntable has numerous sensors to detect the total number of tablets that are passing it.

feed all the tablets into a turntable

Step3: The turntable will continue to transfer the tablets and let them discharge while rotating. There is another sensor located near the discharge funnel. It will ensure the overall accuracy of the counting process.

discharge tablets

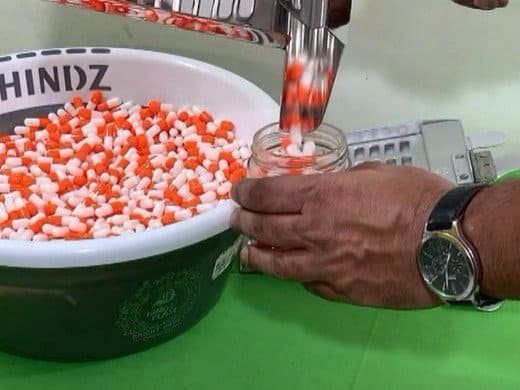

Step4: You can allow a semi-automatic tablet counting machine to fill the bottles as well. This is where you can configure the number of tablets that should go inside a bottle.

Setting the counting number of tablets

How does an automatic tablet count machine work?

You don’t need to do any manual work at all when using an automatic tablet count machine. Here are the steps in detail:

Step1: It will load tablets into the feeding hopper.

pour all tablets inside the feeding hopper

Step2: Then the feeding hopper will place tablets in multi-channel vibratory plates. Through a vibrating mechanism, these plates will properly align and separate the tablets.

Guide tablets in multi channel vibratory plates

Step3: Next, it will guide the tablets to discharge chute via channels. This happens while the vibrating process is still taking place.

The vibrating plate is directing the pills to the discharge chute

Step 4: There is a sensor located at the end of every discharge funnel. Those sensors are responsible for counting the total number of tablets. You can configure how many tablets should go inside a bottle. Then the machine will be able to take care of the job.

counting tablets

Step5: After filling up the bottles, you can allow the machine to transfer them. In other words, the filled bottles will go to the next station via a conveyor belt.

filling tablets into bottles

Applications Of Tablet Counting Machines

There are multiple applications in tablet counting machines. Here are the most prominent applications out of them:

Pharmaceutical Manufacturing

When it comes to manufacturing pharmaceuticals, it is important to count them. This is where tablet counting machines could come into play. Then the manufacturers can determine the right quantities during the manufacturing process

Pharmacies

Pharmacies are mainly responsible for the distribution of pharmaceutical products. But before the distribution, they need to ensure proper counts. This is another application of the tablet counting machines.

Central Filling and Packaging Facilities

Large central fill pharmacies are using advanced tablet counting machines. It helps them with automating the process of filling sachets, pouches, and bottles of pharmaceuticals.

How Accurate Are Tablet Counting Machines?

At the time of buying a tablet counting machine, you need to be mindful about its overall accuracy as well. That’s because the pharmaceutical industry requires a high level of accuracy in terms of counts. The modern semi-automatic and automatic tablet counting machines usually offer a high accuracy. But in manual tablet counting machines, there can be human error. Discrepancies can take place due to:

- Lapses in concentration leading to miscounts

- Difficulty accurately tracking small tablets

- Fatigue setting in over long counting periods

- Confusing similar looking medications

Here are some of the most important factors that contribute towards the accuracy of a tablet counting machine:

- Regular cleaning and calibration

- Avoiding foreign particle obstructions

- Proper tablet loading techniques

- Detecting broken/damaged tablets

- Managing software updates

- Monitoring error reports

This is why you need to follow the vendor best practices when using a tablet counting machine at all times. Then you can experience optimal accuracy rates at any given time.

3 Tips To Buy Tablet Counting Machine

Are you on the lookout to purchase the best tablet counting machine? Then here are 3 important tips that you need to keep in mind.

Understand your needs

The very first step is to understand why you need a tablet counting machine. This is where you need to take a look at factors such as your volumes, workflow, and space availability. Make sure that you don’t ignore the budget. Always prioritize the must-have features, instead of taking a look at the nice to haves.

Inspect the machines in detail

Once you are familiar with your needs, you can go lookout for a one. This is where you need to get in touch with vendors and see what options they have. It is better if you can get them to perform demos on the functionality of the machines the offer. Make sure to assess the overall simplicity, changeovers between medications, and the counting process

Check after sales support

You are investing a considerable amount of money to buy a tablet counting machine. On the other hand, these machines are not very easy to operate as well. That’s why you need to check for after sales support. You need to discuss the maintenance needs with the vendor as well. Then you can check what option provides the most value to you in the long run.

Take Away

Now you have a clear picture of getting a tablet counting machine. Always go ahead with the best machine that can cater to your needs. The upfront cost is important, but make sure that you also consider the long-term savings that automation can offer. On top of everything, you need to be working with a reliable vendor to get the machine. Then you can continue to operate it in the long term, without encountering any issues.