Top 10 Global Tablet Coating Machine Manufacturers In 2025

The Ultimate Guide To Gummy Candy Production Line

What is the Food Emulsifier Machine: Everything You Need To Know

Are you struggling with visually unappealing food because your ingredients won't blend smoothly? Or do you want to enhance the shelf life of your food items so they stay fresh for long? Well, it doesn't matter the situation—a good emulsifier machine can be your savior. It gives your food the perfect texture and a beautiful appearance that's needed in professional settings like commercial kitchens and food production facilities.

In this guide, we'll discuss everything about food emulsifier machines— what they are and how they work. So, continue reading!

What is the Food Emulsifier Machine?

A food emulsifier machine mixes, disperses, emulsifiers, and homogenizes various viscous ingredients. It does this by breaking down and reducing ingredients so they achieve a fine, uniform look.

vacuum mixers

Sausages, purees, and dips are all made using a food emulsifier machine. That is why the global market size of food emulsifiers will hit US$5.6 billion by 2032.

What is an Emulsifier in Food Tech?

An emulsifier in food tech is a chemical compound that emulsifies two immiscible liquids, such as oil and water. In simple words, emulsifiers are additives that allow the suspension of a substance or liquid into the other. This helps in the formation of many industrial and restaurant food recipes.

How Does Food Emulsifier Machine Work?

Now that you are aware of what is an emulsifier machine and its role in the food industry let's look at how a food emulsifier works:

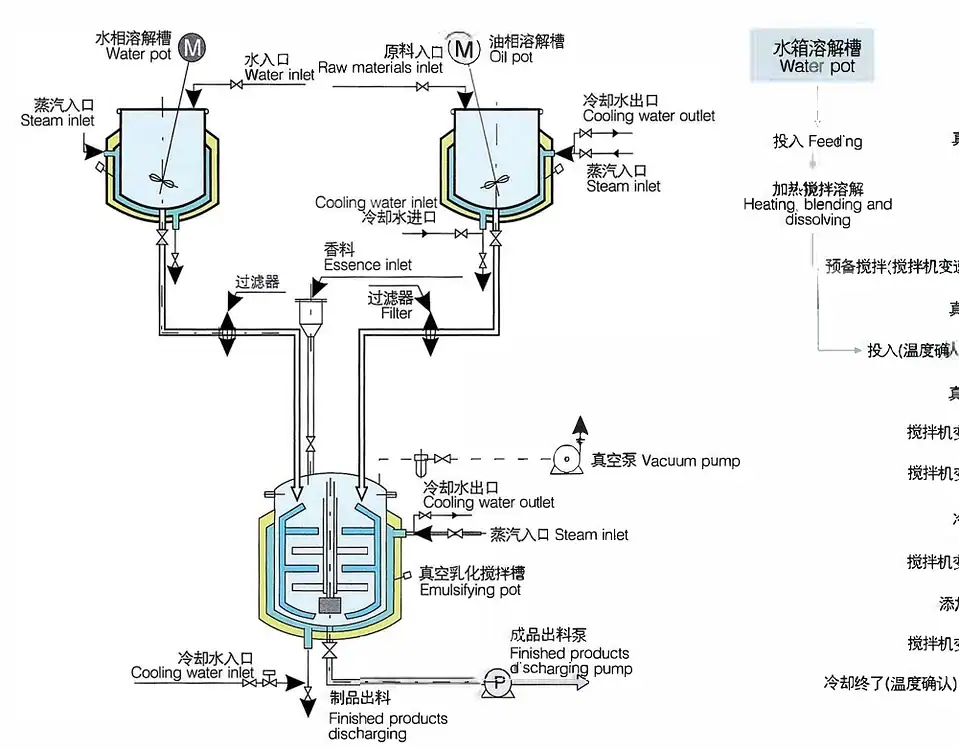

Step 1: Heating and Transferring Ingredients to Emulsifying Pot

The process starts by heating ingredients in two different containers, one having water and the other holding oil. Once you heat them enough, the emulsifying pump sucks both heated solutions. It transfers them into the main emulsifying pot present right beneath the water and oil containers.

Step 2: Mixing with a Scraper

A scraper inside the emulsifying pot immediately gets to work. It blends the ingredients until they are fully mixed and not sticking to the pot’s wall. After the scraper, the central mixing element takes control, further blending for better integration.

Step 3: Cutting and Crushing

There are rotating vanes within the mixer that cut, crush, and blend the ingredients. High-speed cutting wheels work against a stationary cutting cover, reducing the size to a thickness of around 200 nm to 2 µm.

Step 4: Emulsification

In this step, centrifugal force and high-speed hydraulic shearing create a stable emulsion that has a uniform texture with no bubbles.

Step 5: Air Removal

However, to avoid bubble formation in the final product, any air that's produced during mixing is drawn into the vacuum of the emulsifying pot. The final emulsified product settles in the pot and is then released for use or further processing.

Conclusion

Food emulsifier machines are an important part of the food industry. They are useful in blending two immiscible liquids so food experts can experiment with a variety of recipes. They help in the creation of food items like mayonnaise, purees, and dips. They also play a role in extending the shelf life of products. All this happens by allowing moisture retention, even fat distribution, and stalling prevention.